Metal Expansion Joints & Bellows

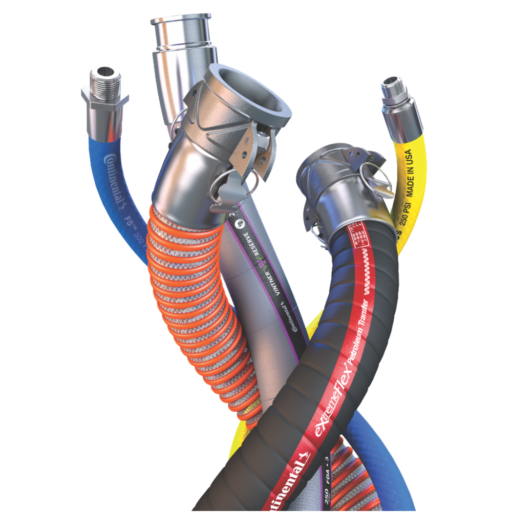

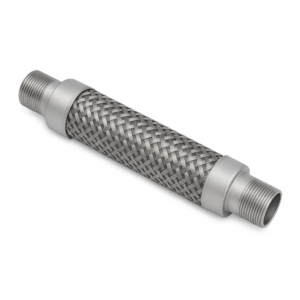

Engineered for demanding piping systems, these metal expansion joints integrate one or more convoluted bellows fabricated from high‑grade stainless steels and alloy materials (such as T‑304, T‑316/316L, T‑310, T‑321, Inconel 625, Hastelloy X/C276, AL6XN) to absorb thermal expansion, vibration, and misalignment across axial, lateral, and angular movement modes . Designed using EJMA‑compliant calculation tools, each assembly includes precision weld‑end fittings or ANSI flanges, and undergoes rigorous testing protocols including hydro and leak tests to ensure long service life under pressure and temperature extremes.

Available in configurations such as single‑ply or multi‑ply bellows, universal, pressure‑balanced, tied, gimbal, hinged, elbow and rectangular types, these joints are optimized for applications in power generation, chemical processing, HVAC, oil & gas, wastewater treatment, and marine exhaust systems.

Compared to non‑metallic alternatives like rubber, the metallic joints handle higher operating temperatures (from −420 °F to +1,500 °F) and pressures (often exceeding 1,000 psi), making them suitable for critical and high‑duty industrial environments

Typical life cycles start at around 1,000 thermal cycles and scale upward depending on material and service conditions. Provisions for custom engineering include reverse‑engineering, rebuild services, and OEM‑specific assemblies—all fabricated in‑house with exacting standards for cycle life and dimensional control.