Dairy processing requires specialized equipment to ensure hygiene, efficiency, and compliance with food safety standards. Choosing the right hose for milk and dairy transfer is essential to maintaining product integrity, preventing contamination, and improving operational efficiency.

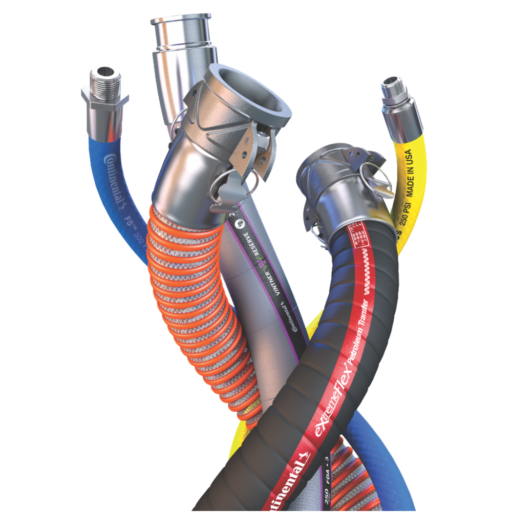

At Capital Rubber, we proudly offer the Rubberworx F0012 Food Transfer Hose, an industry-leading option for dairy applications. We provide a full range of 3A chlorobutyl dairy hoses designed to meet the highest sanitary requirements.

Why Choose the Rubberworx F0012 Food Transfer Hose?

✔ FDA Nitrile Tube for Oil-Based Dairy Products – The F0012 hose features a food-grade nitrile inner tube, making it ideal for dairy transfer applications, including milk, cream, and other oil-based dairy products.

✔ Corrugated Cover for Durability and Flexibility – The specially designed corrugated outer cover enhances durability while maintaining superior flexibility for ease of handling and installation.

✔ Smooth Tube for Microbial Resistance – The ultra-smooth inner tube reduces microbial buildup, ensuring a sanitary transfer environment and simplifying cleaning processes.

✔ 3A Certified with LGV Couplings – Rubberworx hoses paired with LGV couplings provide a fully certified FDA 3A-approved dairy transfer solution, with options for Tri-Clamp and Bevel Seat couplings to meet industry demands.

Common FAQs About Selecting Dairy Hoses

1. Why is a smooth tube important for dairy transfer hoses?

A smooth inner tube minimizes the risk of microbial buildup, making cleaning and sanitation more effective while ensuring the integrity of dairy products.

2. Can this hose handle oil-based dairy products like cream and butterfat?

Yes! The FDA nitrile tube in the Rubberworx F0012 hose is designed specifically for dairy products that contain oils and fats, preventing degradation and maintaining product purity.

3. What are the best couplings for dairy hoses?

For sanitary applications, we recommend LGV-certified Tri-Clamp and Bevel Seat couplings, which meet 3A sanitary standards and allow for secure, leak-proof connections.

4. How often should dairy hoses be replaced?

Routine inspections should be conducted before each use to check for wear, cracks, or stiffness. Regular replacement ensures continued compliance with sanitary regulations and prevents contamination.

5. Why should I choose Capital Rubber for my dairy hose needs?

At Capital Rubber, we provide:

✔ Industry expertise in selecting the best hose and fittings for your dairy processing needs.

✔ Premium brands including Rubberworx.

✔ Certified LGV couplings for fully FDA 3A-compliant dairy transfer solutions.

✔ Fast and reliable service to keep your dairy operations running smoothly.

Trust Capital Rubber for Your Dairy Hose Solutions

Selecting the right dairy hose is essential for ensuring hygiene, efficiency, and compliance in dairy production. Whether you need a flexible transfer hose, high-pressure rated hose, or certified sanitary couplings, Capital Rubber has the expertise and product range to support your dairy processing operations.

Looking for the best dairy hose for your application? Contact Capital Rubber today for expert recommendations and premium dairy transfer solutions!