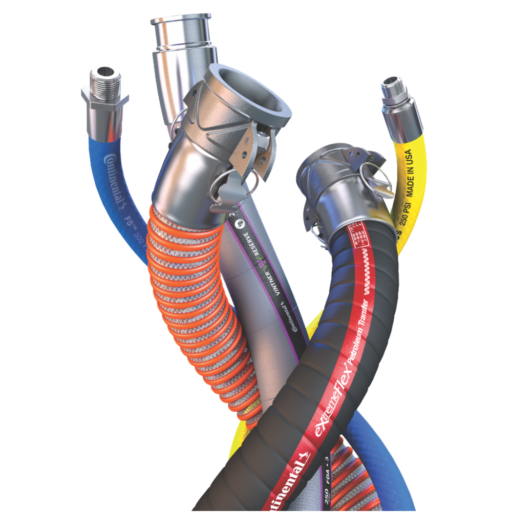

At Capital Rubber & Gasket, we understand that quality is non-negotiable for wineries and breweries. The Continental Vintner™ Wine Hose offers unparalleled reliability, hygiene, and durability—designed specifically to meet the rigors of liquid food transfer.

1. Premium Food‑Grade Liner & Cleanability

The smooth chlorobutyl or EPDM liner is fully FDA/USDA-compliant and conforms to 3‑A Sanitary Standard 18‑03, ensuring a neutral taste profile in wine, beer, or juice. Its homogeneous design prevents microbial buildup and discoloration—vital for product integrity.

2. Robust Reinforcement & Flexibility

Featuring a rustproof monofilament helix offering crush and kink resistance, the Vintner hose retains a slim profile and flexibility—thanks to a strong 4:1 safety factor. It’s lighter than traditional wire hoses, leaving no rubber residue when dragged across surfaces.

3. Exceptional Temperature & Chemical Resistance

With 250 psi working pressure and ability to operate from –30 °F to 220 °F, the Vintner hose handles CIP processes and extreme cleaning agents without degradation. The EPDM tube variant enhances chemical and ozone resistance and improves coupling retention at elevated temps.

4. Certified Quality & Safety

All hoses are built on a chrome mandrel, ensuring hygienic consistency, and meet FDA/USDA and 3‑A 18‑03/18‑02 standards. They’re ideal for both in-plant and tank-truck transfers—providing peace of mind and compliance.

Conclusion

The Continental Vintner™ Wine Hose offers a powerful mix of food-grade purity, rugged resilience, temperature/chemical endurance, and regulatory compliance. At Capital Rubber & Gasket, our team is ready to help you identify the correct hose, fittings, and assembly for your operational needs.

Reach out today to discover how we can support your winery or brewery with top-tier fluid transport solutions!

Frequently Asked Questions

- What sizes are available?

Inner diameters from 1″, 1½”, 2″, 2½” to 3″, with bend radii from 3″ to 12″ depending on size. - What temperature range does it support?

–30 °F to 220 °F (–34 °C to 104 °C) - Is it CIP-compatible?

Yes—designed to resist harsh cleaning agents and CIP processes. - What safety margin is built in?

A 4:1 safety factor with 250 psi working pressure and 1000 psi burst capacity. - Does it affect taste or odor?

No—its liner is homogeneous, plasticizer-free, and won’t impart taste or odor. - What certifications does it meet?

FDA, USDA, and 3‑A 18‑03/18‑02 certified. - Are fittings included?

We offer crimped coupling systems, including Tri‑Clamp fittings and protective rubber rings. - Can it be used for brewery and beverage transfers?

Absolutely—engineered for wine, beer, fruit juice, and non-oily liquids