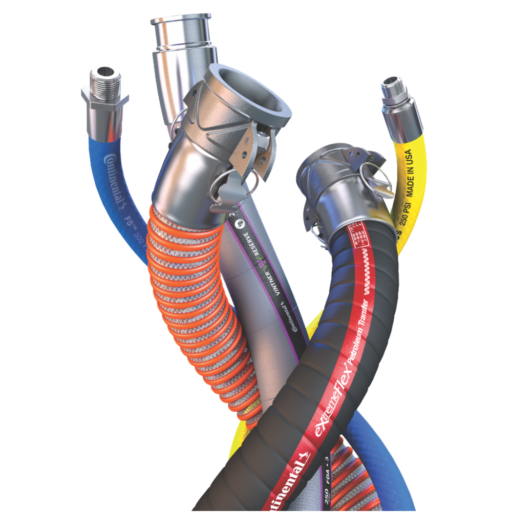

Expansion joints play a crucial role in piping systems by absorbing movement, reducing stress, and ensuring long-term durability. Choosing the right expansion joint for your application is essential to prevent system failures and maintain efficiency. At Capital Rubber, we offer a wide range of expansion joints and expert guidance to help you find the perfect fit for your needs.

Key Considerations When Selecting an Expansion Joint

✔ Measure Movement in All Planes – Understanding how a piping system moves is critical. Expansion joints must accommodate axial, lateral, and angular movement without excessive stress.

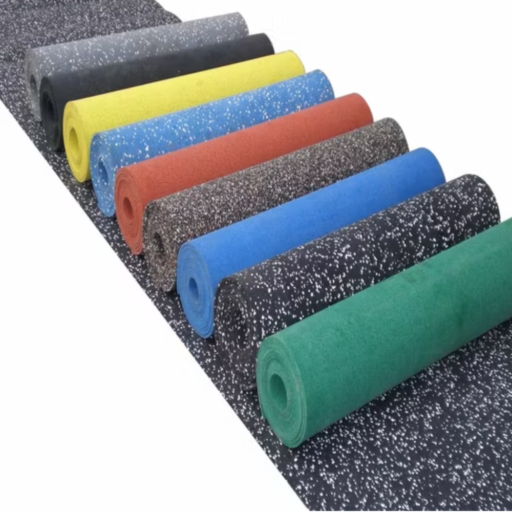

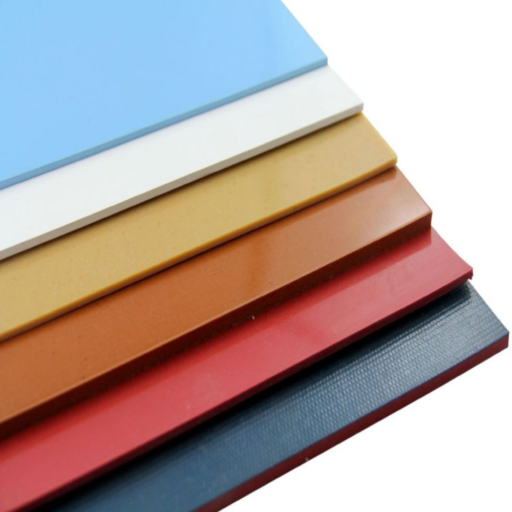

✔ Material Compatibility – Selecting the right material for the application ensures longevity and performance. Common materials include EPDM, Neoprene, and PTFE-lined rubber for chemical resistance.

✔ Pressure and Temperature Ratings – Expansion joints should match the system’s pressure and temperature specifications to prevent premature failure.

✔ Installation Environment – Factors such as UV exposure, chemical exposure, and mechanical wear must be considered when selecting the right expansion joint.

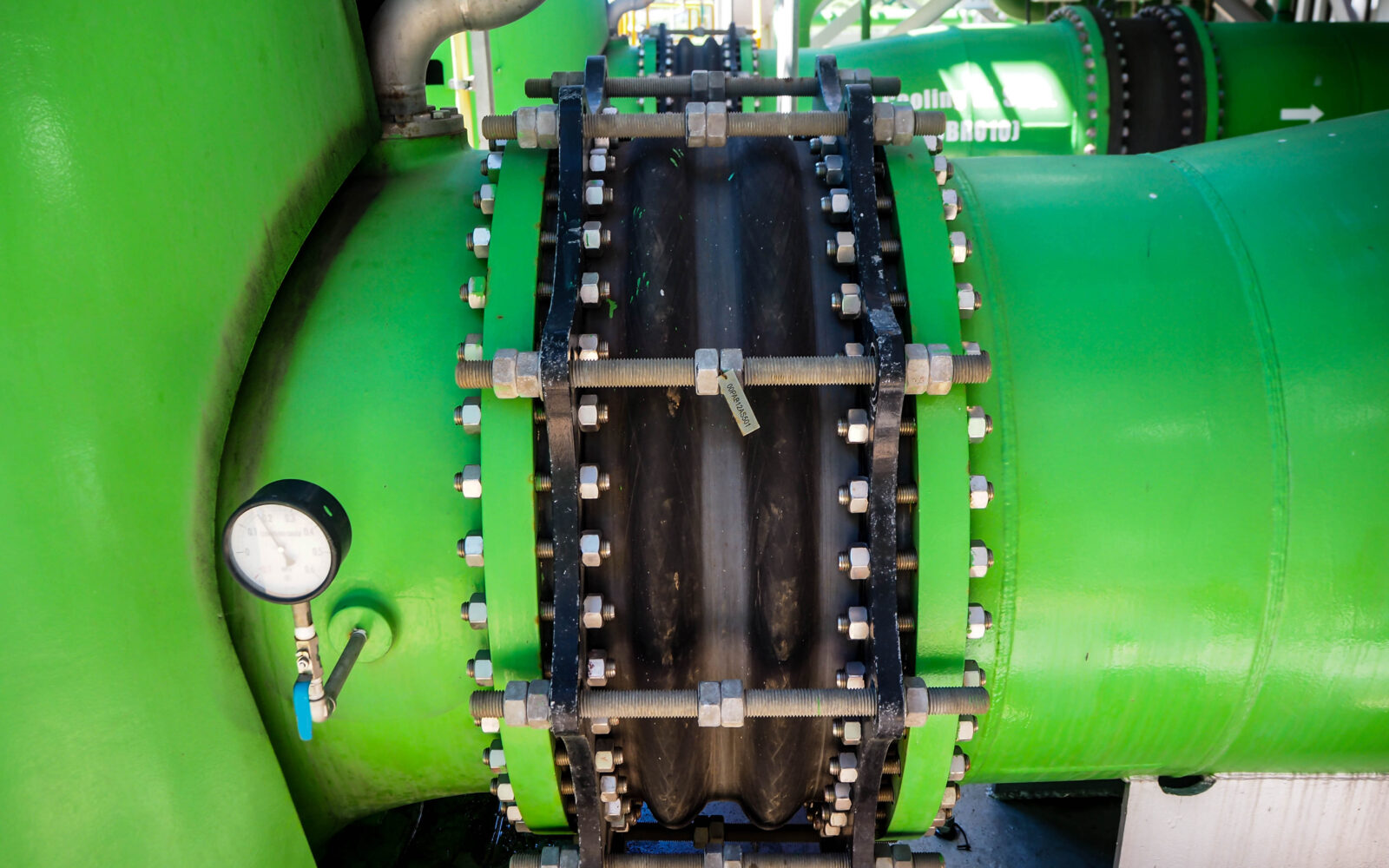

✔ Use of Limiting Rods and Hardware – In applications with high pressure or excessive movement, additional hardware such as limiting rods, control units, and tie rods may be required to prevent overextension or damage.

When to Use Limiting Rods and Other Installation Hardware

Limiting rods and other expansion joint hardware help control movement and prevent overextension, which can lead to failures. Here’s when you should consider adding them:

🔹 High-Pressure Systems – Limiting rods protect against excessive movement due to pressure surges.

🔹 Vibrating Equipment – Control units stabilize expansion joints in systems with heavy vibration.

🔹 Large Thermal Expansion – Tie rods restrict unwanted axial movement in high-temperature applications.

🔹 Piping Misalignment – Hardware assists in compensating for misalignment while maintaining joint integrity.

Common FAQs About Selecting Expansion Joints

1. How do I determine the correct expansion joint size?

Proper sizing involves measuring the pipe diameter, expected movement range, and system pressure. Incorrect sizing can lead to premature wear and inefficiency.

2. What are the most common materials used in expansion joints?

The most common materials include EPDM for water applications, Neoprene for industrial uses, and PTFE-lined rubber for chemical resistance.

3. Can an expansion joint help with noise and vibration reduction?

Yes! Many expansion joints are designed to absorb vibrations and reduce noise, improving overall system performance and longevity.

4. How often should expansion joints be inspected and replaced?

Routine inspections should be conducted every 6 to 12 months, with replacements occurring as needed based on wear, cracking, or loss of flexibility.

5. Why should I consult with Capital Rubber for expansion joint selection?

Our expert team helps customers navigate material selection, movement calculations, and installation requirements to ensure the right fit for every application. We partner with industry leaders to provide top-quality products that meet the highest performance and safety standards.

Trust Capital Rubber for Your Expansion Joint Needs

Selecting the right expansion joint is crucial for system efficiency and longevity. Whether you need a standard joint or a specialized solution, Capital Rubber’s experts can help you make the best choice for your application.

Need assistance with your expansion joint selection? Contact Capital Rubber today for expert guidance and premium sealing solutions!