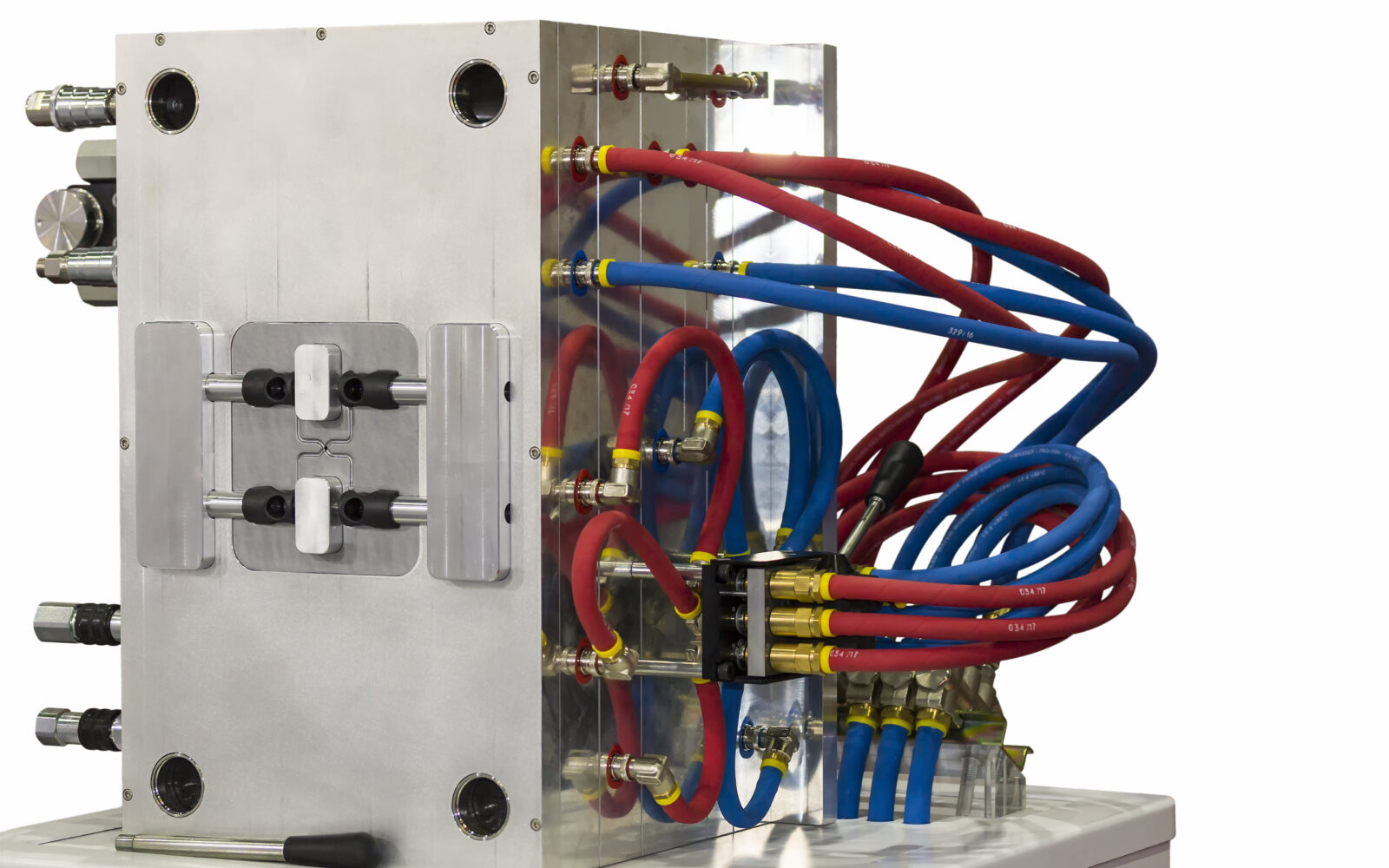

The injection molding industry requires high-performance hoses, expansion joints, and hydraulic components to maintain efficiency and reduce downtime. Whether handling plastic pellets, managing hydraulic systems, or maintaining material transfer, selecting the right products is critical to achieving consistent production output. Capital Rubber is California’s premier supplier, offering a one-stop shop for all injection molding facility needs.

Why Choose Capital Rubber for Injection Molding Applications?

At Capital Rubber, we provide a comprehensive range of high-quality products tailored to the unique demands of injection molding operations:

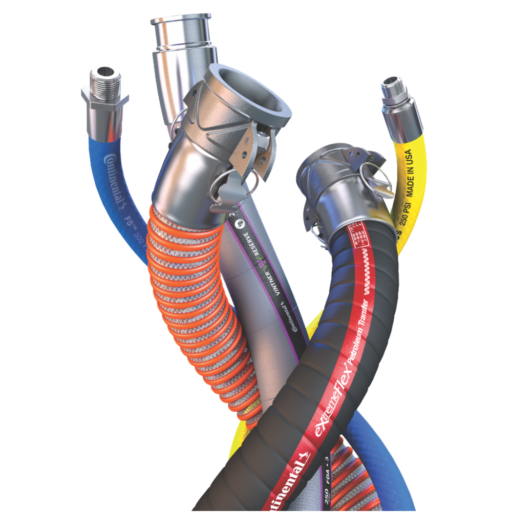

✔ Kuriyama PVC & Urethane Material Handling Hoses – Designed for efficient plastic pellet transfer, offering superior abrasion resistance and flexibility.

✔ Continental Insta-Lock Hose – A secure and reliable hose solution for industrial material transfer, ensuring leak-free operations.

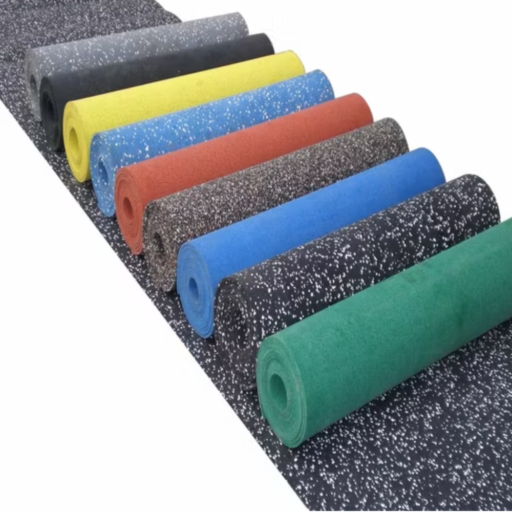

✔ Proco Expansion Joints – Essential for absorbing movement, reducing system stress, and extending the lifespan of critical piping and equipment.

✔ Gates Hydraulic Hose – Industry-leading hydraulic solutions for powering molding machinery and auxiliary equipment.

With Capital Rubber, injection molding facilities across California get access to the most reliable and durable products to keep operations running at peak efficiency.

Common FAQs About Injection Molding Hose & Expansion Joint Selection

1. What type of hose is best for plastic pellet transfer?

For plastic pellet transfer, Kuriyama PVC and urethane hoses are the best choices due to their high abrasion resistance, flexibility, and lightweight design. These hoses help prevent clogs and reduce wear in material transfer systems.

2. Why is the Continental Insta-Lock hose recommended for injection molding facilities?

The Continental Insta-Lock hose provides secure, leak-proof connections for material transfer applications. Its durability and easy-to-use design make it ideal for high-volume industrial operations like injection molding.

3. How do expansion joints benefit injection molding systems?

Proco Expansion Joints help protect equipment by absorbing vibration, thermal expansion, and movement in piping systems. This prevents stress-related failures and extends the life of machinery and infrastructure.

4. What hydraulic hose should I use for injection molding machines?

We recommend Gates Hydraulic Hoses for injection molding machinery because they offer high-pressure performance, superior flexibility, and resistance to extreme temperatures and oil exposure.

5. Why should injection molding facilities choose Capital Rubber?

✔ Expert Guidance – Our team helps facilities select the right hoses, fittings, and expansion joints for their specific needs.

✔ Industry-Leading Brands – We supply products from Kuriyama, Continental, Proco, and Gates, ensuring the highest quality.

✔ One-Stop Shop – We provide material handling, hydraulic, and expansion solutions all in one place.

✔ Fast & Reliable Service – We understand that downtime costs money, so we prioritize quick turnaround and reliable product availability.

Optimize Your Injection Molding Operations with Capital Rubber

If you need durable, high-performance solutions for your injection molding facility in California, Capital Rubber has you covered. From plastic pellet handling to hydraulic systems, we provide everything you need to keep your operation running efficiently.

Looking for the best hose and expansion joint solutions for your facility? Contact Capital Rubber today for expert assistance and premium products!