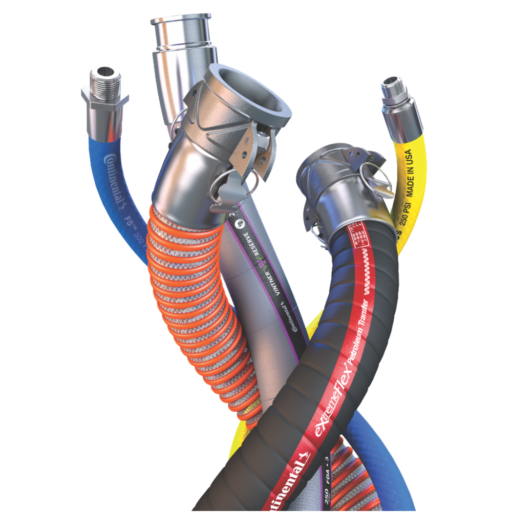

Efficient and safe transfer of dry food materials requires high-quality, specialized hoses that prevent contamination and static buildup. The Kuriyama VoltBuster hose is designed specifically for dry food transfer applications, ensuring compliance with food safety standards while addressing the challenges of static electricity.

Why Choose the Kuriyama VoltBuster Hose for Dry Food Transfer?

Kuriyama’s VoltBuster hose is engineered to provide superior performance in dry food material transfer, offering the following key benefits:

✔Static Dissipation – The hose is constructed with a static dissipative cover and reinforcement to minimize static buildup, reducing the risk of sparks and product contamination.

✔ FDA & USDA Compliance – Manufactured with food-grade materials, VoltBuster hoses meet strict safety regulations for dry food transfer applications.

✔ Abrasion Resistance – Designed to withstand wear from continuous dry bulk material movement, extending the lifespan of the hose.

✔ Lightweight & Flexible – Easy handling and installation, making it an ideal solution for food processing facilities requiring frequent hose adjustments.

✔ High Flow Efficiency – Smooth interior walls reduce product buildup and maintain consistent flow rates, improving overall efficiency.

Common FAQs About Static Buildup in Dry Food Transfer Applications

1. Why is static electricity a concern in dry food transfer?

Static buildup occurs when dry food particles move through a hose, creating friction between the material and hose walls. This buildup can lead to sparks, dust ignition, and even contamination, making static-dissipative hoses like VoltBuster essential for safety.

2. How does the Kuriyama VoltBuster hose prevent static buildup?

The VoltBuster hose features a static-dissipative cover and reinforcement that safely dissipates static charges, preventing electrostatic discharges that could pose risks to workers and food safety.

3. What types of dry food materials can be transferred using the VoltBuster hose?

This hose is ideal for transferring:

- Flour & grains

- Sugar & powdered sweeteners

- Coffee beans & grounds

- Cereals & snack foods

- Dried spices & powders

- Powdered dairy products

4. What safety standards does the VoltBuster hose meet?

Kuriyama VoltBuster hoses comply with FDA, USDA, and 3-A sanitary standards, ensuring that food contact surfaces remain safe and contamination-free.

5. How often should the VoltBuster hose be inspected for wear and tear?

Routine inspections should be performed weekly or monthly, depending on usage. Look for signs of wear, internal abrasion, or any visible damage to ensure the hose remains in optimal working condition.

6. Can the VoltBuster hose be used in pneumatic conveying systems?

Yes! The VoltBuster hose is designed for use in both gravity-fed and pneumatic conveying systems, making it a versatile choice for various food processing operations.

Optimize Your Dry Food Transfer with Kuriyama VoltBuster

Choosing the right hose for dry food transfer is critical to maintaining food safety, preventing contamination, and ensuring operational efficiency. The Kuriyama VoltBuster hose is the ideal solution, providing superior static control, durability, and compliance with food safety standards.

Need help selecting the right hose for your application? Contact Capital Rubber today to learn more about the Kuriyama VoltBuster and how it can enhance your dry food transfer operations!