As consumer demand for specialty and high-quality breads continues to grow across California, bakeries must adapt by utilizing conveyor belts that enhance efficiency, hygiene, and performance. The right conveyor belt plays a critical role in producing everything from artisan sourdough in San Francisco to gluten-free loaves in Sacramento.

Key Factors in Choosing the Right Bakery Conveyor Belt

1️⃣ Flexibility for Seamless Transitions

- Ensures minimal product loss and improved throughput.

- Necessary for high-speed automated production lines.

2️⃣ Optimizing Grip, Release, and Feed Rates

- Prevents sticking, tearing, or deformation of baked goods.

- Critical for sheeting, proofing, and packaging processes.

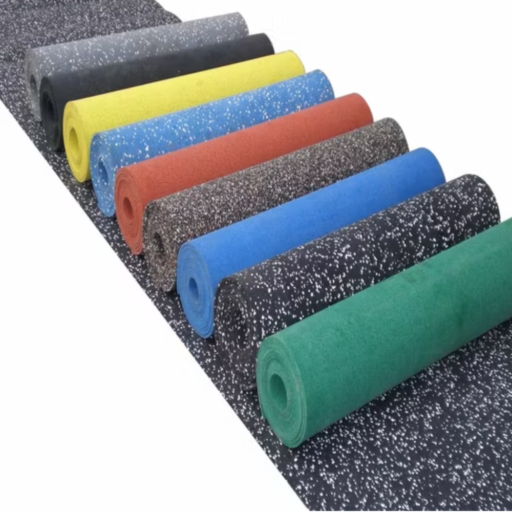

3️⃣ Belt Compatibility with Ingredients & Baking Conditions

- Must withstand high heat, humidity, and oils to ensure durability and easy sanitation.

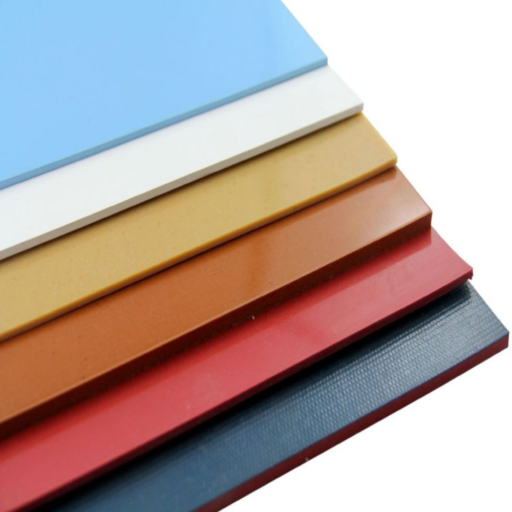

4️⃣ Compliance with Food Safety Standards

- HACCP-compliant belts meet California’s strict food safety regulations.

- Seamless, thermoplastic belts eliminate contamination risks.

Why Choose Capital Rubber?

Capital Rubber provides high-performance bakery conveyor belts designed for California’s growing baking industry. Whether you run a local artisan bakery or a high-volume bread production facility, we offer:

✔ Food-grade belts from top manufacturers

✔ Expert guidance in belt selection

✔ Fast turnaround and reliable support

Contact Capital Rubber today to enhance your bakery’s production efficiency!