What is Minimum Bend Radius & Why Does It Matter?

The minimum bend radius is the smallest curve a hose can be bent without causing damage, kinking, or flow restriction. Bending a hose too tightly can lead to:

❌ Restricted Flow – Kinks reduce efficiency and increase pressure buildup.

❌ Structural Weakening – Excessive bending weakens the hose walls, leading to failure.

❌ Leaks & Ruptures – Over time, improper bending can cause hazardous failures.

Factors That Affect Minimum Bend Radius

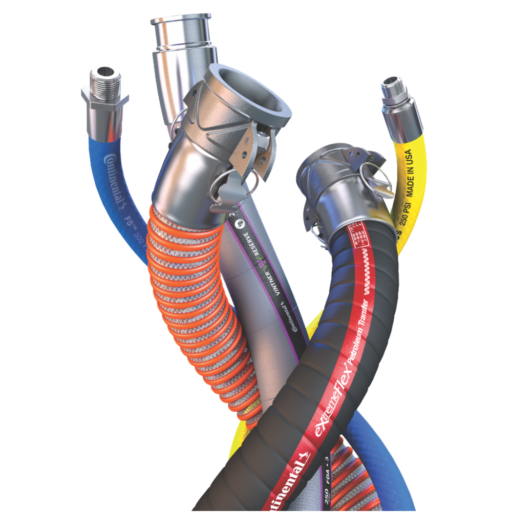

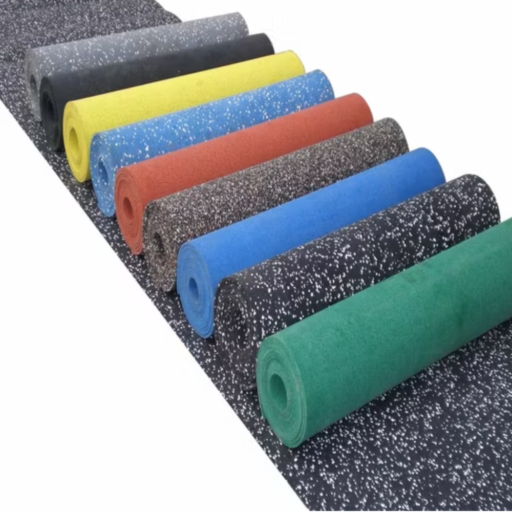

🔹 Material Type – Rubber hoses are more flexible, while metal and thermoplastic hoses require larger bend radii.

🔹 Reinforcement Layers – Braided vs. spiral-wound reinforcements impact flexibility.

🔹 Temperature Conditions – Extreme heat softens hoses; extreme cold causes stiffness.

🔹 Pressure Rating – Higher-pressure hoses require a larger bend radius.

Best Practices for Proper Hose Installation

✔ Use the Largest Possible Bend Radius – Allow hoses to curve naturally.

✔ Avoid Sharp Bends Near Fittings – Maintain at least 18 inches of straight hose before bends.

✔ Use Hose Supports & Clamps – Prevent sagging and excessive bending.

✔ Factor in Temperature & Pressure – Select hoses designed for real-world conditions.

✔ Inspect Hoses Regularly – Look for signs of stress, leaks, or damage before failure occurs.

Need Expert Assistance?

Proper hose selection and installation improve safety, efficiency, and cost savings. Need help finding the right hose for your application? Contact Capital Rubber today!